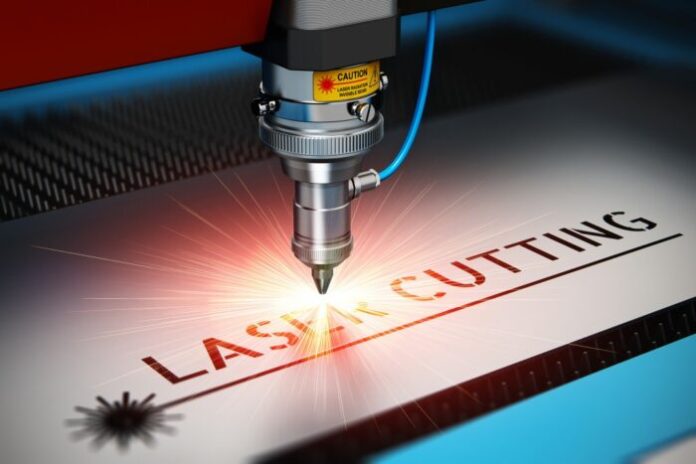

Do you want markings on stainless steel? The process is called laser engraving and if you haven’t heard about it, it turns out to be very effective and precise. The way it works is that a powerful laser beam is directed to the steel surface and it vaporizes it and this is what it is in simple terms. You can rest assured that the marking will stay there permanently, but be careful because once it is done, you will not be able to make corrections.

What’s it for?

Laser Engraving is great for everyone who wants to leave a mark on a steel surface whether for marketing purposes or to use it as a gift. For example, often you will find trophies and plaques to be engraved as well as rings.

So now that we explained closely what laser engraving is and where it is commonly used, let’s move on to 6 best practices for the process:

1. Focus on Power

Not many people are aware of this, but you should not do this quickly. Instead, as confirmed by Emitlaser that has a variety of engravers, you should cut more deeply. The reason for this is that deeper markings will sustain any wear and tear more easily. Of course, you should also consider what it is for and what kind of steel you are working on.

This is easily adjusted on the machine that allows you to set the depth as well as the speed. It goes without saying that doing it slowly makes it more precise.

2. Each Project is a Separate Endeavor

Bear in mind that not all of your projects would be the same. People tend to relax as they complete one task after another, thinking that they cannot make a mistake. And while the room for error is small, you should be careful.

Every time, the surface you are working on is different and the configuration needs to fit the surface as well as the planned engraving. Therefore, configuring and calibrating the machine each time is essential for it to be successful. Don’t forget that once you make a mistake, there’s no turning back.

And that leads us to our next point.

3. Practice Makes Perfect

It is safe to say that you cannot start right away and do it without any mistake. Just like with any other job, laser engraving requires practice in order for you to reach excellence. Therefore, whenever you have some stainless steel that you don’t have a purpose for, use it to practice. Try instilling different markings and experiment a bit with settings.

Learn all there is about different machines and try them out whenever you have a chance. This will build up confidence in your work and you will be much better at it over time.

4. Safety Is Important

Whether you are doing this professionally or you are just messing around, make sure you wear all the necessary safety gear. Wear a proper mask to protect your face. The reason for it is that when nickel and chromium particles are released and they can be harmful to your health.

Make sure to always keep in mind the safety procedure that takes place when you are working with lasers, no matter how experienced you are.

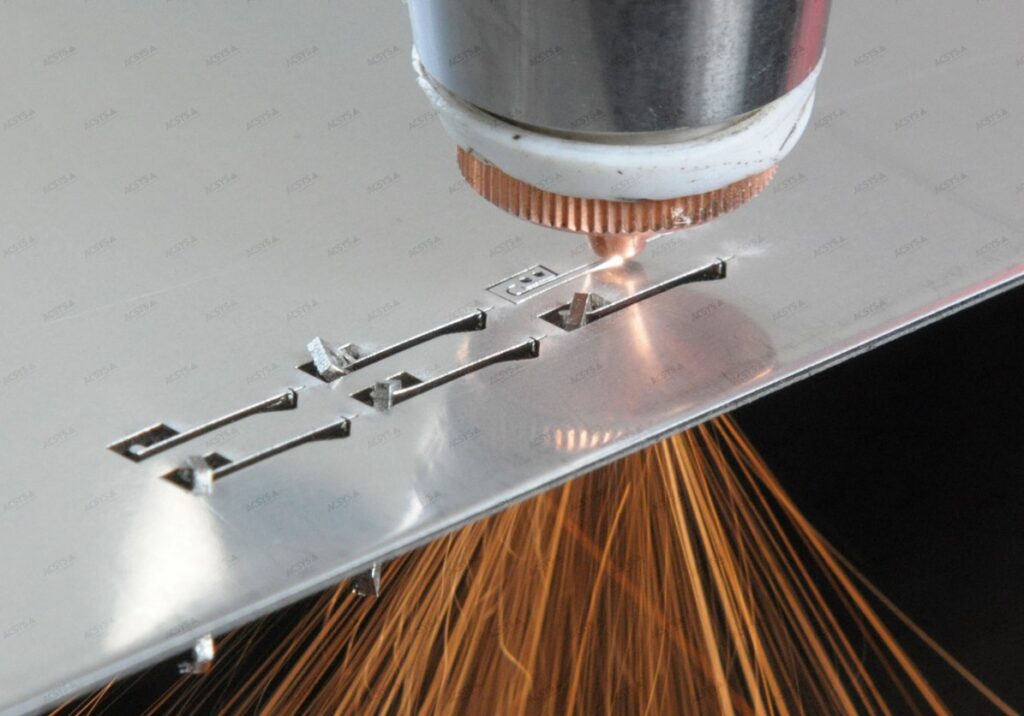

5. Multiple Laser Passes Are Required

When you are using only one laser passes you will quickly realize that the final marking will be a thin line and it will not look very good. Furthermore, this leaves a waste product known as slag and not only will it look bad, but it is dirty as well, preventing you from completing your work.

Slag is easily avoided if you use multiple laser passes. And once again, here, going slower at slightly higher power is advised.

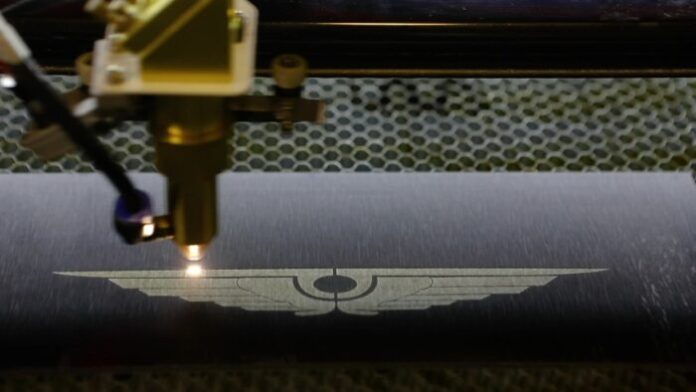

6. Simple Designs

Laser engraving is just one of the processes for stainless steel design. There are many others one of which is laser etching. There are various differences between the two, but we will not get into details here.

What you need to know is that laser engraving is a complicated process and when you are creating the designs, you should keep it as simple and as straight as possible. The reason for it is that it is way more powerful than the etching and there’s not too much you can do in terms of contrasting elements and creating a richer image.

It comes to no surprise that the process found its widest application with serial numbers and date codes while for more subtle work, other processes are used.

Conclusion

Hopefully, you will find these 6 laser practices to be of use, whether you are just getting into the laser engraving yourself, or you are interested in the process so that you know what to expect from someone who is working on an item.

We want to repeat that if you are starting to work with steel, put your safety first and do practice regularly before you start working on certain projects. Also, it is great to use cheaper material for practice as they will go to waste anyway, like engraving bricks for the start. Even so, bear in mind that materials act differently when you direct the laser to them, so find stainless steel is the best choice.

![Calgary’s Hottest Neighborhoods for Luxury Homebuyers [2024]](https://thewashingtonote.com/wp-content/uploads/2024/04/Calgary-324x160.png)