In laboratory settings, the choice of countertops is critical to ensure a safe, durable, and efficient work environment. Epoxy lab countertops have emerged as a popular choice due to their exceptional qualities. Combining functionality with a visually appealing design, epoxy lab countertops offer numerous advantages over traditional countertop materials.

In this article, we will delve into the features, benefits, applications, and maintenance tips for epoxy lab countertops.

Features of Epoxy Lab Countertops

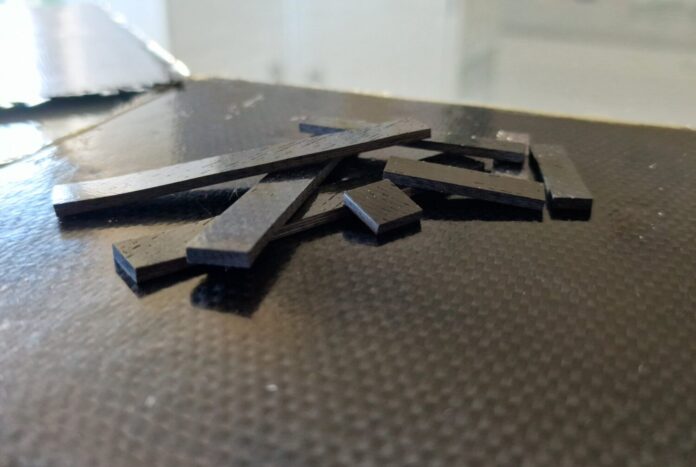

Epoxy lab countertops are constructed using a combination of epoxy resin and a variety of fillers, resulting in a durable and chemically resistant surface. Here are some key features of epoxy lab countertops:

Chemical Resistance: Epoxy countertops have excellent resistance to a wide range of chemicals, including acids, solvents, and reagents commonly used in laboratory experiments. This quality ensures the longevity of the countertops and protects against damage caused by chemical spills or exposure.

Durability: Epoxy lab countertops are highly durable and capable of withstanding heavy usage, impacts, and abrasions. Their robust nature makes them ideal for handling laboratory equipment and materials without compromising their structural integrity.

Non-Porous Surface: The non-porous nature of epoxy countertops makes them impervious to liquids and prevents the absorption of chemicals, stains, and contaminants. This characteristic ensures a hygienic working surface that can be easily cleaned and disinfected.

Customizability: Epoxy lab countertops offer design flexibility, allowing for customization to meet specific laboratory requirements. They are available in a range of colors and patterns, enabling the creation of an aesthetically pleasing workspace that reflects the laboratory’s style and ambiance.

Benefits of Epoxy Lab Countertops

Choosing epoxy lab countertops brings several benefits to laboratory settings:

Chemical Resistance: The superior chemical resistance of epoxy countertops safeguards against corrosion and damage caused by harsh chemicals, ensuring a long-lasting and reliable work surface.

Safety: Epoxy lab countertops are non-combustible and have low smoke and flame spread properties, adding an extra layer of safety to the laboratory environment.

Hygiene: The non-porous surface of epoxy countertops prevents the growth of bacteria, fungi, and molds, reducing the risk of contamination and maintaining a clean and sterile workspace.

Ergonomics: Epoxy countertops can be customized to include integrated sinks, drip trays, or grooves, promoting efficient workflow and easy disposal of liquids and waste materials.

Applications of Epoxy Lab Countertops

Epoxy lab countertops find extensive applications in various laboratory settings, including:

Chemical Laboratories: The chemical resistance of epoxy countertops makes them an ideal choice for laboratories conducting research, testing, and analysis involving corrosive chemicals.

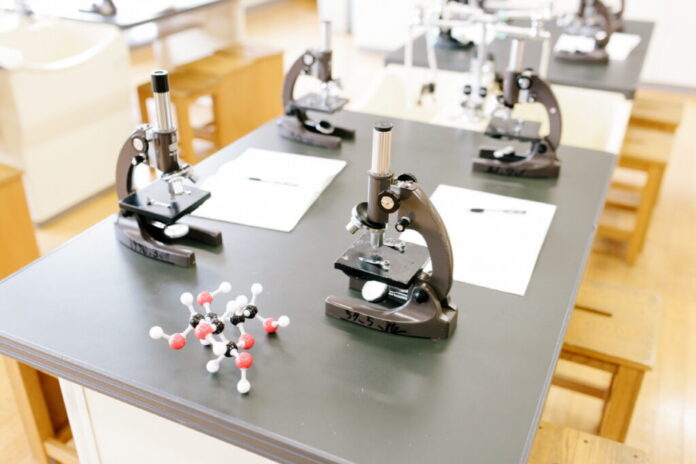

Educational Institutions: Epoxy lab countertops are widely used in educational institutions, such as schools and universities, where they provide a safe and durable surface for science laboratories and classrooms.

Medical and Healthcare Facilities: Epoxy countertops are suitable for medical and healthcare facilities, including hospitals, clinics, and research labs, as they can withstand the demands of rigorous sterilization procedures and offer a hygienic working environment.

Maintenance Tips

To maintain the longevity and appearance of epoxy lab countertops, consider the following maintenance tips:

Routine Cleaning: Regularly clean the countertops with mild soap or a recommended non-abrasive cleaner. Avoid using harsh chemicals or abrasive scrubbers that could potentially damage the surface.

Immediate Spill Cleanup: Promptly clean up any spills to prevent staining or etching on the surface. Use a suitable cleaner and a soft cloth or sponge to remove the spill, and rinse thoroughly.

Heat Protection: While epoxy countertops have heat-resistant properties, it is best to use trivets or hot pads when placing hot objects on the surface to prevent potential thermal damage.

Cost

One of the main factors to consider when choosing a countertop material for your lab is the cost. Epoxy resin countertops are relatively affordable, with prices typically ranging from $100 to $200 per square foot. These prices include both the material itself and the cost of installation. In comparison, alternatives like stainless steel or natural stone may cost significantly more.

However, it’s crucial to bear in mind that epoxy resin offers superior durability, resistance to chemicals, and ease of maintenance. Over time, these benefits can lead to significant cost savings, making epoxy a highly cost-effective option for laboratories on a budget.

Limitations

Like any material, epoxy resin has its limitations. While it’s renowned for its impressive resistance to heat and chemicals, it can be more susceptible to scratches and impacts compared to materials like stainless steel. For this reason, it’s essential to handle sharp objects with care to maintain the surface’s smoothness.

Another consideration is that the installation of epoxy countertops requires professional expertise to ensure proper curing and avoid issues like bubbling or uneven surfaces.

Despite these limitations, with proper care and handling, epoxy resin can provide a long-lasting and durable surface for your laboratory.

Environmental Impact

Epoxy resin countertops are not without environmental considerations. The production of epoxy involves petroleum-based materials, contributing to the industry’s overall carbon footprint. However, manufacturers are increasingly adopting more sustainable practices such as utilizing plant-based alternatives where possible.

In terms of recyclability, epoxy resin is not easily recycled due to its strong, cross-linked structure. Yet, its long lifespan and durability may counterbalance this issue by reducing the frequency of replacement.

It’s important to choose manufacturers who adhere to environmentally responsible practices, thus ensuring that your laboratory stays committed to sustainability while benefiting from the unparalleled functionality of epoxy resin countertops.

Comparative Analysis

When considering lab countertop options, it’s vital to understand how epoxy resin measures up against other common materials. Stainless steel, a popular choice for its robustness, falls short in chemical resistance compared to epoxy, which remains unaffected by most laboratory chemicals.

Phenolic resin, another contender, provides excellent durability and chemical resistance, much like epoxy. However, it can’t match epoxy’s resistance to heat and moisture.

Granite countertops, while visually appealing and heat-resistant, are porous, making them prone to staining, unlike epoxy which offers a seamless, stain-resistant surface.

Furthermore, granite’s susceptibility to damage from acids and other corrosive substances makes epoxy a more practical choice for labs.

While each material has its merits, epoxy resin countertops provide an unrivaled balance of chemical and heat resistance, durability, and cost-effectiveness. The choice, of course, depends on your specific lab needs, but for comprehensive functionality and aesthetics, epoxy resin often proves to be a superior choice.

Conclusion:

Epoxy lab countertops offer a perfect blend of functionality, durability, and aesthetic appeal for laboratory environments. Their chemical resistance, durability, easy maintenance, and customization options make them an ideal choice for various laboratory applications.

By investing in epoxy lab countertops, laboratories can enhance safety, efficiency, and overall aesthetics, creating a productive and visually pleasing workspace.

![Calgary’s Hottest Neighborhoods for Luxury Homebuyers [2024]](https://thewashingtonote.com/wp-content/uploads/2024/04/Calgary-324x160.png)