Recently, the awareness of the search for alternative heating and cooling solutions has been increasing. In many ways, scientists manage to come up with energy-efficient solutions that are ideal for each individual. It is this awareness that has led to the creation of plate heat exchanger, which is ahead of energy efficiency.

Do We Know What Energy Efficiency Really Is?

Energy efficiency means reducing energy consumption for the production and life of people. It is often misinterpreted as energy saving, which inevitably leads to a decrease in quality of life. However, being energy efficient means that energy is used intelligently, without giving up. To achieve this, different measures are applied, which may be technical or behavioural changes. The first type of measures implies that the devices we use have a high degree of efficiency. Or to be more precise, devices that have low losses when converting one form of energy to another.

What Can Individuals Do About Energy Efficiency?

The lack of using energy-efficiency solutions is ultimately reflected in the larger bills. Therefore, house-owners should also have an interest in improving this segment of their lives. How to save money on energy bills, make your home more comfortable and help reduce environmental pollution? The answer is – by investing in energy-efficient solutions, such as new doors and windows, facade adaptation. But it also refers to heating equipment, thermal insulation or photovoltaic panels, heat pumps, etc. And of course, plate heat exchangers. These are mostly used in industry, but can also be very effective in households.

What Are Plate Heat Exchangers?

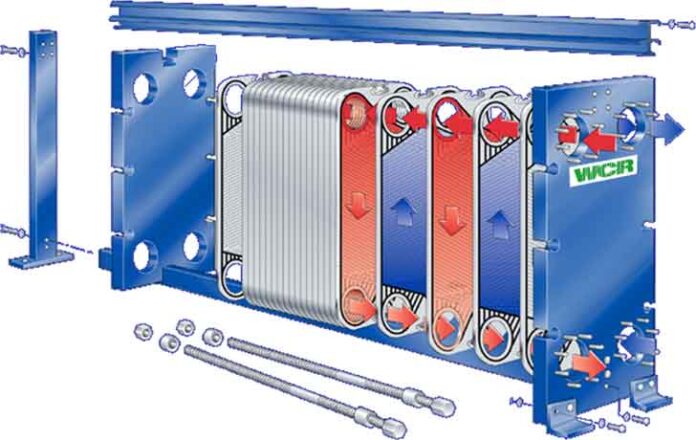

Plate heat exchangers are simple in design devices often included in schemes of different types of industrial equipment. Sometimes they are used in home cooling and air conditioning systems. As you can already assume by the name, these appliances are produced to take the heat from one medium and transfer it to another.

Main Varieties Of Heat Exchanger

In specialized equipment, different types of similar devices can be used. However, the most economical, efficient and popular type is the plate heat exchanger. Its working principle is based on the simple transfer of heat through metal. Such devices can be used for various purposes.

Contemporary Plate Heat Exchanger: Operating Principles

A device of this type operates in a cross-sectional scheme. The sections are alternately filled with heated and cooled medium. The heat exchange between them takes place through the plates. The filling of parts during the operation of the device provides seals of various shapes. The latter may either allow the medium to pass or delay operating. Generally, this is a very simple working principle. The plate heat exchangers are arranged so that the media in them moves towards each other. This is how all such devices work. The operation principle of a plate heat exchanger is the same as for models intended for air conditioning, cooling lubricants, etc. The only difference is in the types of media that pass through the fuselage. In the hot water model, that is water, in other devices of this type, there may be an exchange between solutions, oils, gases, etc. For these reasons, plate heat exchangers are well suited for use within high energy consuming industrial companies. It is this method that can provide great savings and thus better productivity.

Technical Specifications

You can find plenty of manufacturers in the market, but we advise you to choose carefully. Experienced manufacturers, such as Exodraft, can tailor these devices to the specific requirements of customers. Keep in mind that heat exchangers have a wide range of applications. When choosing a plate heat exchanger, you should always pay attention to indicators such as:

- Power

- Expense

- Material and surface of panels

- Sealant material

- Operating temperature

- Permissible particle size in media

- Maximum operating pressure

Design Of The Plate Heat Exchanger Elements

Now we know the operating principles of a plate heat exchanger. But, what about its elements? In each plate exchanger, there are 2 holes below the media. Besides, these devices may have a relief that facilitates the direction of passage of liquids or gases. Their thickness depends on the purpose and size of the device, as well as pressure. These exchanger elements are constantly in an aggressive environment. Therefore, they must be made of a material that is as stable as possible. For that reason, these panels are usually made of stainless steel. This steel contains molybdenum and is characterized by increased resistance to corrosion, damage and chloride exposure. In case the aggressive media does not pass through the heat exchanger, the common metals can be used to make the plates. Very often these elements are made of titanium or titanium palladium.

Heat Sealers

The durability and reliability of the heat exchanger are depending on the quality of heat sealers. These seals prevent the media from mixing. They’re also directing them along a specific path. Currently, only two types of heat sealers are used in heat exchange – clamp and glue. Rubber materials are usually used to produce gaskets. The adhesives are attached in special grooves to the epoxy. Plunger variants are installed using special bonding elements.

Power And Consumption

Using a plate heat exchanger, and benefits of its working principle and design can be very suitable in different sectors of the economy. Therefore, the power of such devices varies over a fairly wide range. Until now, heat exchangers ranged from several hundred kilowatts to tens of megawatts. They have been used in different types of heating and cooling systems. This indicator depends mainly on the number of plates used in the device and their dimensions.

Scope Of Application

A plate heat exchanger and its operating principles can be incorporated into systems of different structures:

- In mechanical engineering. When using such and similar devices, cold lubricants, hydraulics, etc.

- With plunger and turbine engines.

- In power plants.

- With compressors.

- In delivery. On ships, heat exchangers are mainly used for central cooling.

- In the light industry.

- In mechanical engineering and metalworking.

- In heating and air conditioning.

A modern plate heat exchangers can be considered reliable, efficient and suitable for use. All of this makes their use in different types of cooling and heating systems more than reasonable and cost-effective.