Getting your own barcode for the products you mean to mass produce and sell is an important step towards building your own brand. It is also one of the last things you must accomplish before you can truly start working in the industry you mean to be a part of. Naturally, there is a lot of confusion surrounding purchasing and owning barcodes for one’s goods. How it is done? What do you need in order to apply for one? Where do you even apply and who do you talk to? While it may sound difficult and challenging, in reality it is much easier and straightforward. In this article, you will learn why purchasing barcodes is not nearly as difficult as it may look or sound. If you wish to learn more about this, make sure to check out legalbarcode.com.

The Barcode Phenomenon

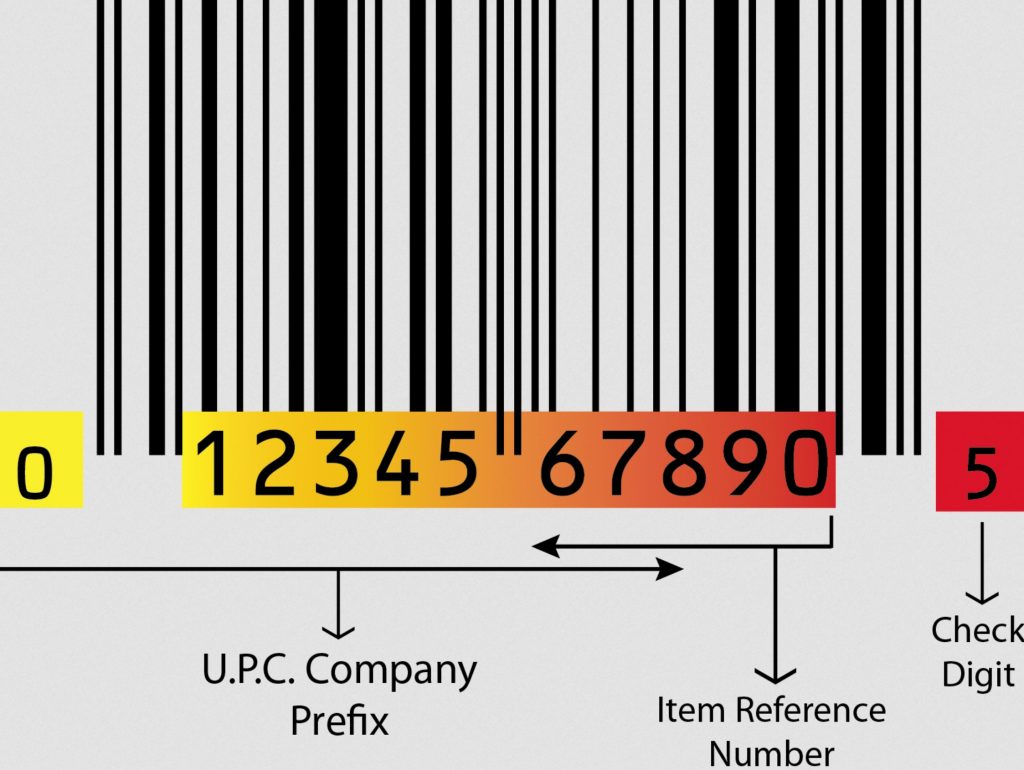

Barcodes changed the way business is being done at least when it comes to the process of buying and selling individual goods. Each different product has to have a unique identifier, one that is globally unique and up to the worldwide standards that exist. For example, the United States use UPC (unique product number) barcodes, numbers that are made of two components. The first is the UPC Company Prefix and the other is the Product Number. Together, they make a whole barcode.

There are three simple steps in obtaining a barcode for your product and they are very easy to follow and fulfil. They include applying for the UPC company prefix, assigning unique product numbers, and determining how the products will display the barcodes before you apply them. In the following sections we will go over each of the steps in greater detail.

Before we do that, there are certain things to consider on your end. For example, you have to think about how many barcodes you actually need. Then, you should have a general idea of the label your products will use and where the barcodes will go exactly. Finally, you should consider any special requests for the image the codes have and how you can separate yourself from the competition. Once you have a general idea, it will be easier to go through the three-step process.

1. Applying for the Company Prefix

The first and therefore the most important step in this whole process is getting your license and membership and becoming UPS barcode eligible. The company prefix will mark you as the manufacturer of the product in the supply chain. The length of the prefix, as well as the price, depends on the unique items in the process of identification. These numbers can have anywhere from 6 to 10 characters, which again depends on the number of products. For example, a small company that only deals with a single product will have a number of 10 digits. Every variation of color, material, and size needs a different UPC. This means that navy and khaki pants need different identification, and each size needs its own. This process also includes decisions on the payment and fees since the number of UPCs and the annual costs differ based on the length of prefixes.

2. Assigning UPCs

When you have your company prefix in order, it is time to assign every different product their own number. For example, let us stick with the pants from the previous step. If your main variety are khaki pants, they should be the ones to start from. Your company prefix is 012345 for example. The S size of the khaki pants would then be 00001, M is 00002, and L is 00003. Then come the navy pants. Their S is 00004, M is 00005, and L is 00006. You see the pattern? It is easy, but you should think of the system and determine the numbers yourself. Each variety requires a specific number combination. Company prefixes with 6 digits can use 5 extra digits, while those with 9 digit prefixes can use only 2. This is arguably the most overwhelming step but the crucial one since you will be assigning your goods with their identification for the market.

3. Marking the Products

It must feel good to finally have the whole barcodes set for each and every product you are selling. The next step on this seemingly difficult road is to think about what the packaging will look like and where the barcode mark will be. If you are dealing with labels (and you probably are), and they have been printed, you can simply stick them to your boxes by hand. This is not always the most logical nor convenient way of doing this as printing the original artwork of the box with the barcode automatically included is more cost effective and less time consuming. Incorporate the barcode file (with the .eps extension) into the package and label design and it will all be much easier. Once you have your packaging in order, your product will be ready for shipping and waiting to be picked up by customers.

While it is common for companies to print their packaging and labels before they initiate the UPC barcode obtaining process, you should really be doing it properly and think about it all on time. Waiting for the labels and applying them is more work than having your packaging ready with the barcode already there. Electronic format artwork is all the designers and prints need to effectively give you the final packaging box so make sure to collaborate with them if you want a high level of precision and timely efficiency.

Conclusion and Takeaways

All in all, you have by now probably realized that the process of obtaining your own barcodes for the products you mean to manufacture and sell is not at all hard. It makes sense and it is as easy and straightforward as it can be. However, before you begin, you have to have all the ideas and wishes about the look and feel of the final product packaging and label design set. This is why it helps to have it all written down and decided well before you initiate the process and apply for the company prefix.