If you choose to invest in warehousing, you wouldn’t be making mistakes. However, there are some fundamental decisions you need to make to ensure you get it right from the very beginning. Among them is the type of warehouse storage you want to install.

According to RTL, warehouse storage is simply the system in your warehouse where you place the goods to be stored. There are different types of storage in use today. The choice of the best storage for you will depend on the type of inventory you want to focus on, the available space, and your budget, among other factors. This article will discuss some of the most popular warehouse storage, their design, features, and application.

1. Static Shelving

Static shelving is designed for lightweight goods. They are immovable, and goods stored in them are usually manually sorted. They do not support forklifts. Once these shelves are placed in a particular position in the warehouse, they cannot be adjusted. Hence, it is essential to consider what you want before you install static shelving critically. In most cases, these kinds of warehouse storage shelves are usually used for goods stored for a short term and replaced. But they are space-friendly as many of these shelves can be located close to one another in a warehouse.

Because they cannot be loaded by a forklift, they can only hold inventory that can be carried by hands. Such inventories include clothes and clothing materials, agricultural products, books, and light component parts.

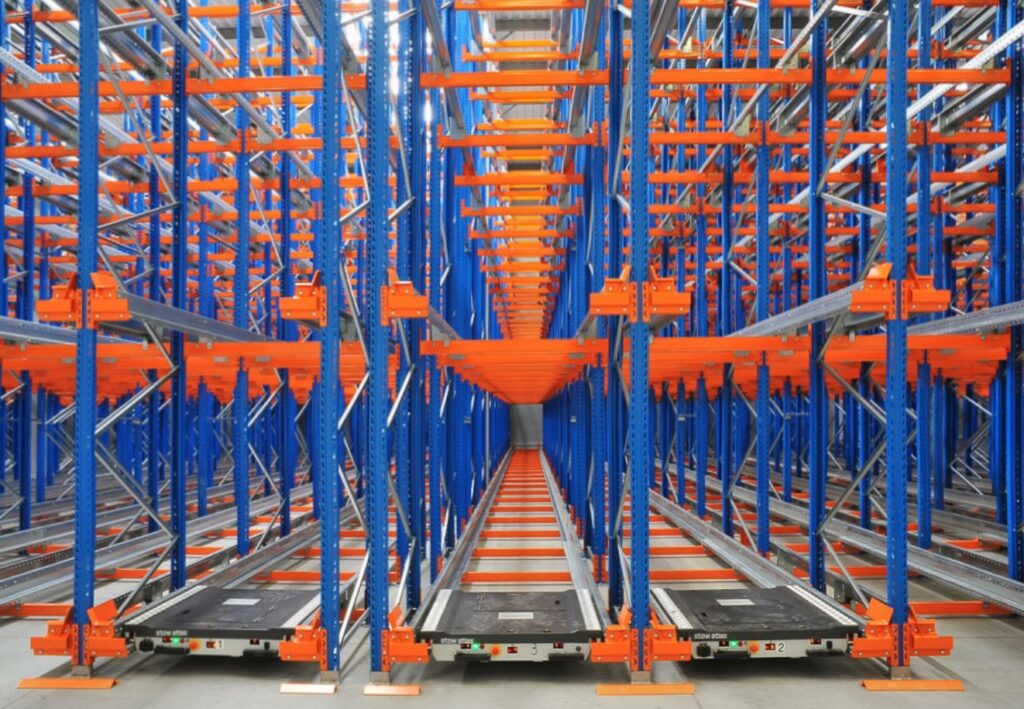

2. Pallet Storage System

Pallet racking is usually used to store goods that come in boxes. They can handle heavy objects and are compatible with forklifts. They can also be automated. The storage system is constructed with pallets that can be metallic, plastic, or wood. They come with different maximum weight capacity, and it is very critical to stick to the weight limit. The pallets can be designed to run the entire height of the warehouse, stacking one on another. With this arrangement, they can hold a large amount of inventory in a small space. This makes this option a great way to manage space. Hence, it is the most popular among warehouse storage systems.

There are many types of pallet racking. The common ones include High Bay Racking, which has its racks connected to the walls and the roof, hence has excellent space to store inventory. To retrieve the stored good, automation is usually employed. Vertical Ranking System has metal arms to strengthen it as it is designed for stocks that are long and placed vertically in the warehouse. Gravity Flow Racking makes use of rollers that are inclined such that they can move under the influence of gravity with much effort. Cantilever Ranking is used for long objects like wood, pipes, and boards. As the name suggests, the beam is fixed at one end and free at the other.

Other important Pallet Storage subcategories include Drive-in Ranking, Drive-through Ranking, Narrow Aisle Ranking, Push Back Ranking, Carton Flow Ranking, Pallet Live Ranking, and Shuttle Ranking.

3. Multi-Tier Racking

A multi-tier storage system uses several decks stack on one another in a vertical column that can run from the floor to the ceiling. They are usually used for lightweight inventories and are organized manually. This storage system is ideal for inventories that come in large stocks of small unit size and lightweight. To fully safe space, you can pack goods as densely as possible on the tier.

One advantage of this storage system is that it is very flexible, and you can add or remove the tier according to the need at the moment. However, they are usually static, and as they can run to the ceiling, it is vital to provide an effective way of navigating through this system. One of the major ways of achieving this is by constructing staircases in locations that will provide easy access to the decks.

4. Mobile Shelving

As the name implies, mobile shelving is constructed on systems that can move. They are usually placed on rails or carriage. Apart from the mobility, mobile shelving and static shelving are similar in most of their other features. Inventories stored in mobile shelving are usually manually sorted and are continuously replaced. However, mobile shelving can store more inventories than static shelving in the same space. Therefore they are great in saving space, and if you have a big warehouse, it will be easy to implement mobile shelving and another storage system together.

Among the major considerations in installing this storage system are the track system and whether it will be automated. The track can be on the floor, but it can also be on top. Also, the system can be manually operated, and it can be mechanized.

5. Mezzanine Flooring

Mezzanine flooring might be expensive to construct but is worth any amount you spend on it. The floor is constructed above the floor you are using for the major warehousing and can provide extra space for storage. You can also use the mezzanine floor for other purposes like checking stocks. Being a separate floor, you can include all features you want like conveyor and lift.

Depending on your need, the mezzanine floor does not necessarily be a single floor. It can extend to the third and fourth floor if you so wish.

6. Software solutions for warehousing

When installing a storage system, think about process automation. A quality Warehouse Management Software (WMS) can help you increase the productivity of your warehouse processes. In addition, you can integrate your WMS with other software like ERP, CMS, CRM. By combining your entire soft into one network, you simplify or fully automate most of your business processes. In this guide, you will learn how to improve your logistics processes.

Other Options

There are still many other storage system options you can choose from. Among them is the storage cabinet, which uses cabinets to store inventories. Wire partitions use wire cages to store goods. These cages are installed in such a way that they can also be quickly removed when there is no more need for them. Another option is a deep double racking, which is a kind of pallet storage system, but it uses double pallets that are placed back to back to save space.

The Take-Away

There is no one-size-fits-all in the warehouse storage system. The option that would be best for you will depend on the kind of inventory you want to focus on, the available space, and your budget. However, it is possible to combine different warehouse storage systems. It is also possible to install flexible systems. However, most of the common warehouse storage are great, and any option you go for will surely serve the intended purpose.